In the age of smart manufacturing, factory tours are no longer just “walk-through visits.” The aerial viewing corridor is becoming the hidden ace of modern factory layout design — not only optimizing production efficiency but also transforming the factory into a living “technology exhibition.” In this blog post, Shoebill Technology, a professional lean manufacturing plant layout service provider, will share the four core advantages of smart factory planning layout in the Industry 4.0 Era.

Spatial Revolution: Secret Behind 20% Capacity Boost

In traditional factories, visitor walkways often occupy valuable production space. By elevating the passage into an aerial walkway, the design releases floor area, directly improving production capacity by up to 20%.

This innovation allows for a lean manufacturing plant layout, where production zones are no longer segmented by pathways. The result is a more compact equipment arrangement, smoother logistics, and a natural surge in operational efficiency.

Visual Impact: Industrial Aesthetics” of Bird’s-Eye View

Standing on the aerial walkway, visitors can take in the precision, order, and automation of the entire production line from above. This bird’s-eye perspective delivers a powerful visual impact — enabling customers to truly experience the intelligence and beauty of the production process.

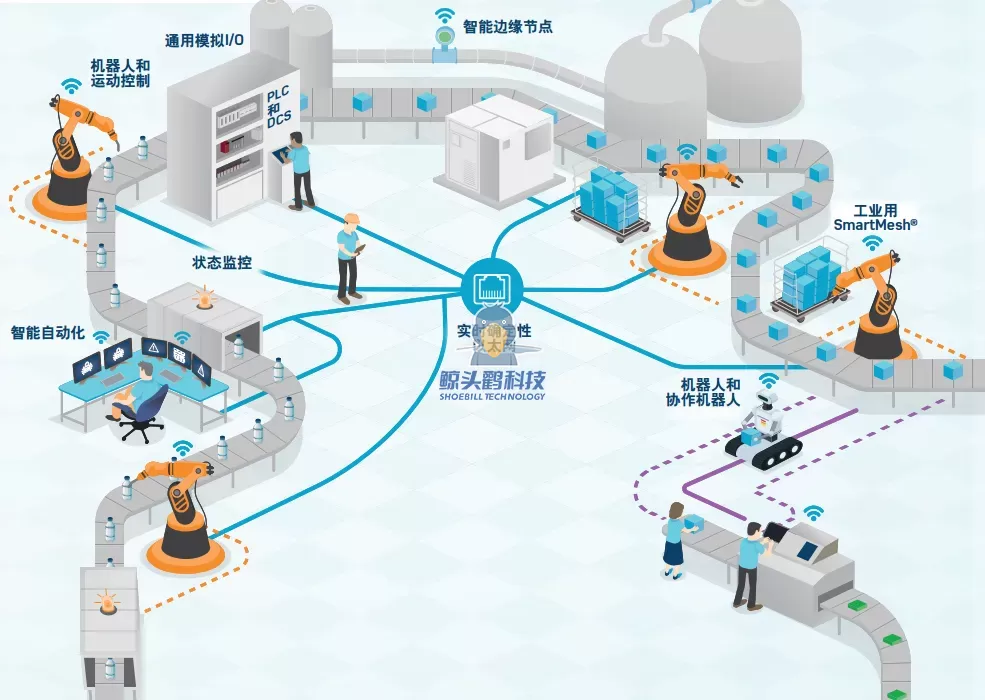

It’s not just a tour; it’s an industrial art exhibition, showcasing how smart systems, robotics, and automation harmonize within a modern smart factory layout design.

Policy and Market Dual Drive: Accelerating Smart Transformation

As policies promoting digitalization and green manufacturing gain momentum, more enterprises are integrating aerial walkways into their lean manufacturing plant layout to meet both operational and marketing needs.

The corridor not only enhances the visiting experience but also aligns with global sustainability goals by optimizing building space, reducing material waste, and improving process transparency — all hallmarks of the Industry 4.0 philosophy.

Safety and Efficiency: Human-Vehicle Separation, Zero Interference

The aerial walkway achieves complete separation between people and logistics:

No forklifts, no cross-traffic. Visitors and equipment never share the same route, eliminating safety risks.

Short, efficient tour paths. The linear, elevated route enables a full factory tour in just 10 minutes — maximizing visitor experience while maintaining production integrity.

This level of smart factory layout design ensures both safety and efficiency, a vital feature of advanced lean manufacturing plants.

Hidden Utility: Maximizing Every Inch of Space

By relocating auxiliary rooms — such as power distribution, tool storage, or maintenance spaces — to the lower or mezzanine levels, the main workshop is completely “slimmed down.”

Ground-level areas are fully dedicated to key production equipment, increasing space utilization by over 30%. Every square meter now serves productivity, embodying the philosophy of lean manufacturing plant layout — efficiency without compromise.

Conclusion

The aerial viewing corridor is more than a functional structure — it’s the “invisible marketing officer” of the factory. It allows clients to witness production strength firsthand, gives employees a sense of pride, and even turns the site into a social media hotspot.

In the future, every truly smart factory layout design may come standard with such an “aerial landscape,” blending manufacturing excellence with architectural innovation — transforming the factory from a mere production site into a brand experience destination.