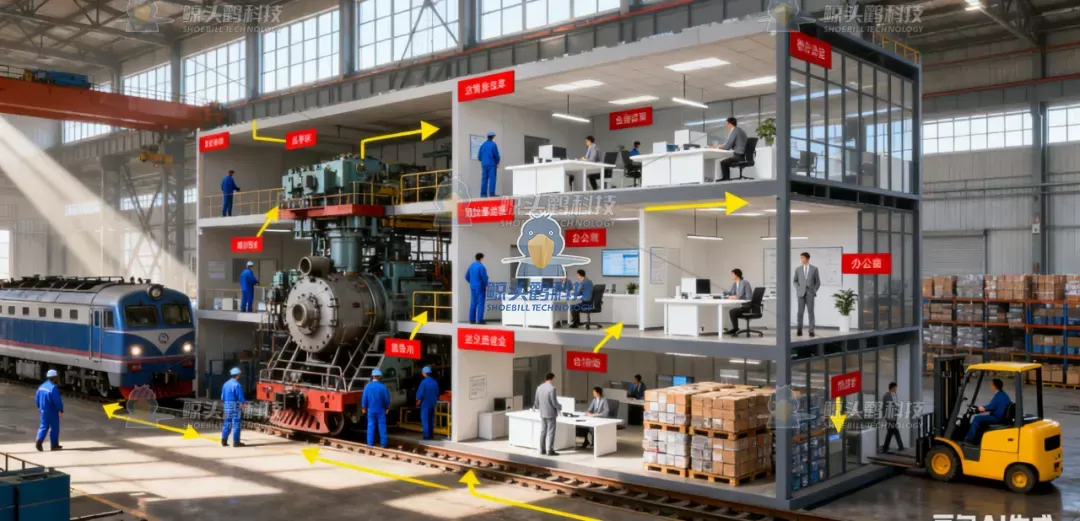

In the industrial architecture field, one design has been called “the sexiest factory” — the single-block multi-level locomotive factory. It breaks away from the traditional flat layout of industrial spaces, achieving efficiency, compactness, and intelligence. Even technology giants like Xiaomi have drawn inspiration from its design philosophy. In this blog post, Shoebill Technology, a professional lean factory planning layout service provider, will share the features of single-block multi-level locomotive factory design.

U-Shaped Structure + Multi-Level Design: Extreme Space Utilization

This factory adopts a U-shaped structure as its main architectural form. Covering only 30 acres of land, it achieves a total floor area of 60,000 square meters through vertical expansion. The multi-level design not only saves land costs but also integrates production, office, and storage functions within one structure. It embodies the essence of a lean factory planning layout, where every cubic meter of space contributes to the production flow — truly realizing the concept of “one building equals one industrial chain.”

Seamless Integration of Office and Production

The ground floor is designated as an office area, with a central elevator connecting directly to all seven floors. This thoughtful vertical connection optimizes the movement paths of both employees and materials. By shortening cross-regional collaboration distances, the design greatly reduces time waste — an ideal solution for high-tech manufacturing industries that demand agility and responsiveness. Such a configuration fully reflects the lean layout philosophy, which emphasizes minimizing non-value-added movement within a production environment.

Dual Function Top Floor: Leisure Meets Green Energy

The top level is cleverly divided into two distinct zones: one half serves as a leisure and reception area to enhance employee well-being, while the other half is covered with photovoltaic panels to generate clean energy for the facility. This dual-purpose space not only demonstrates sustainable design thinking but also brings human warmth into industrial architecture. Integrating renewable energy into the lean factory planning layout further amplifies efficiency while supporting environmental responsibility.

Clustered Equipment Arrangement: Maximizing Efficiency

The factory adopts a clustered equipment layout, arranging production modules in a compact, modular manner to eliminate redundant space. At the same time, flexibility is built in for future production line upgrades. This smart and adaptable configuration perfectly fits industries that require rapid iteration, such as intelligent hardware manufacturing. The lean factory layout approach ensures that workflows remain streamlined, material handling distances are minimized, and space utilization reaches its optimal state.

Central Logistics Hub: The Core of Lean Operation

The logistics dock and automated storage system are strategically placed in the factory’s center, forming a “radiating” logistics network. This setup increases material inflow and outflow efficiency by over 30%, achieving true “zero-distance transfer.” It serves as a textbook case of lean factory planning layout, where centralized logistics enables faster, smoother, and more controlled production processes.

A Prototype of the Factory of the Future

From its U-shaped structure to its vertical logistics core, this single-block multi-level locomotive factory goes far beyond the conventional “large and scattered” industrial complex. It represents the pinnacle of spatial utilization and the next generation of lean factory planning layout. More than just an architectural marvel, it’s a benchmark for intelligent manufacturing — no wonder even Xiaomi couldn’t resist paying homage to it.

[Shanghai Shoebill Technology]

Shoebill Technology will help you plan a user-friendly and affordable industry-leading factory!

Whether you're building a new plant or renovating an existing one, we offer comprehensive, one-stop services, including park planning, architectural design, layout planning, automation and logistics design, standardized industrial interior design, digital design, smart campuses, advanced visualization, and implementation support.

We prioritize implementation, ensuring your project becomes an industry benchmark upon implementation.

Clients include industry leaders such as Heli Forklift, Qianjiang Motorcycle, Giti Tire, Baoxiniao, and Yangquan Valve.

Mobile: 13262659820

Official Website: www.shoebilltech.com

Email: shoebill@balaena.cn