Defining Smart Factory Planning Layout in the Digital Manufacturing Era

In today’s era of digital transformation, the concept of smart factory planning layout goes far beyond traditional production optimization. It integrates lean manufacturing, automation, and data-driven decision-making to achieve seamless collaboration between people, machines, and materials. In this blog post, Shoebill Technology, a high quality lean factory design service provider, will share the six core principles of smart factory planning layout — lean production, lean logistics, optimal inventory, automation with reduced labor, visitor-friendly design, and safety and environmental protection. These principles form the structural and operational foundation of a truly intelligent manufacturing ecosystem.

Lean Production Principles in Smart Factory Layout Design

At the heart of Shoebill Technology’s smart factory layout design is lean production. The company adopts a pull-based production model to synchronize processes from suppliers to end assembly, reducing overproduction and minimizing waste. By blending batch flow with one-piece flow production modes, the layout enables flexible response to varying production volumes and customization demands.

Moreover, Shoebill integrates ergonomic design concepts into workstations, ensuring both productivity and operator comfort. This human-centered design enhances precision, minimizes fatigue, and improves quality stability — key factors in maintaining high-performance manufacturing environments. The result is a production line that achieves optimal efficiency while preserving the well-being of workers.

Optimizing Material Flow Through Lean Logistics Planning

A critical pillar of smart factory logistics layout is the seamless integration of materials and information flow. Shoebill Technology enforces strict segregation of people, vehicles, and materials to eliminate safety risks and congestion. Its layout designs emphasize one-way, non-repetitive logistics routes that minimize movement and eliminate backtracking.

By leveraging intelligent scheduling systems, the company optimizes transportation frequency and reduces travel distance, cutting logistics equivalence to the minimum possible level. The streamlined logistics network not only reduces operational costs but also improves traceability and production rhythm — essential for achieving synchronized manufacturing.

Achieving Optimal Inventory Through Smart Supply Strategies

Inventory management is another crucial dimension in Shoebill’s smart factory planning framework. Guided by the principles of “Just-in-Time” (JIT), Shoebill designs layouts that harmonize Make-to-Order (MTO) and Make-to-Stock (MTS) strategies. This hybrid model allows factories to adapt to changing market demands while maintaining high responsiveness.

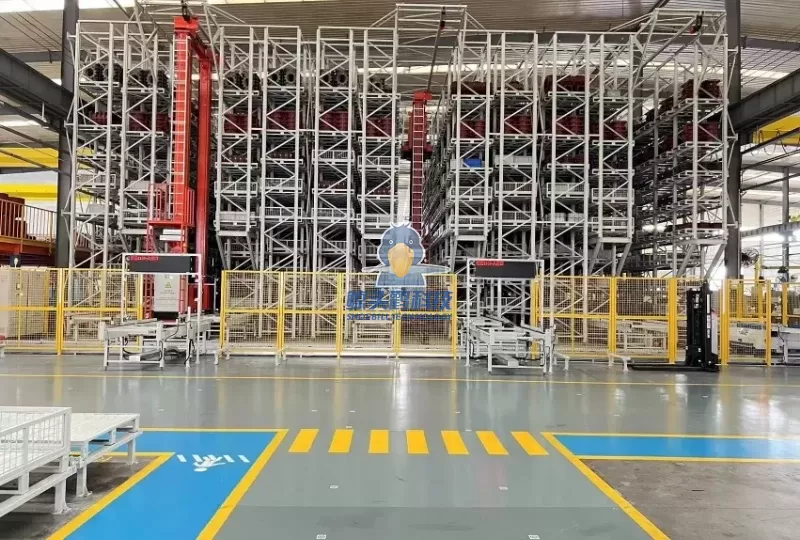

The integration of automated high-bay warehouses (AS/RS) and intelligent replenishment systems ensures minimal inventory levels without compromising supply stability. By reducing material handling time and improving turnover rates, the factory layout supports dynamic balance between production efficiency and inventory cost control — the essence of lean manufacturing intelligence.

Automation and Reduced Labor as a Structural Design Principle

Automation lies at the core of Shoebill Technology’s smart manufacturing layout planning. The company promotes “automation with reduced labor” rather than full automation, emphasizing a balanced approach between technology and human capability.

Shoebill strategically positions automated guided vehicles (AGVs), robotic arms, and intelligent inspection systems throughout the layout to minimize manual intervention while preserving flexibility in complex or customized operations. This design principle not only improves throughput but also builds resilience against workforce fluctuations, laying the foundation for a sustainable, future-ready factory model.

Visitor-Friendly Layouts: Integrating Transparency and Experience

A hallmark of Shoebill Technology’s intelligent factory layout design is its attention to visitor experience. Modern manufacturing spaces are increasingly open to clients, partners, and educational visitors. Shoebill incorporates “visitor-friendly” elements into its factory planning, including transparent production zones, tiered observation pathways, and dedicated routes that ensure safety and non-interference with production activities.

In a recent Southern Trina workshop project, Shoebill positioned the brake caliper assembly area adjacent to the automated warehouse, significantly reducing material transfer distance while enabling visitors to observe advanced manufacturing processes through designated observation corridors. This approach demonstrates how production efficiency and public engagement can coexist harmoniously in a modern smart factory environment.

Safety and Environmental Protection in Smart Factory Planning

Safety and environmental protection are not auxiliary considerations — they are embedded within every smart factory layout concept. Shoebill Technology implements comprehensive safety zoning, ergonomic pathways, and fire-resistant materials to ensure both human safety and equipment reliability.

Furthermore, the layout integrates green manufacturing concepts, such as energy-efficient lighting, intelligent ventilation, and real-time environmental monitoring systems. Through these sustainable measures, Shoebill’s factory layouts align industrial productivity with ecological responsibility, embodying the next generation of clean and intelligent manufacturing spaces.

A Holistic Framework for Future of Smart Factory Development

Shoebill Technology’s six core principles form a unified framework that redefines smart factory planning layout for the modern industrial landscape. From lean production flow to visitor engagement, every design element is interconnected, data-driven, and purpose-built to support long-term operational excellence.

By combining scientific planning, automation intelligence, and human-centered design, Shoebill Technology not only delivers efficient production environments but also creates spaces that inspire innovation, transparency, and sustainable growth. Its approach represents a blueprint for the factories of tomorrow — smart, agile, and deeply attuned to both performance and purpose.