Unveiling Four Core Strategies of Smart Logistics Planning

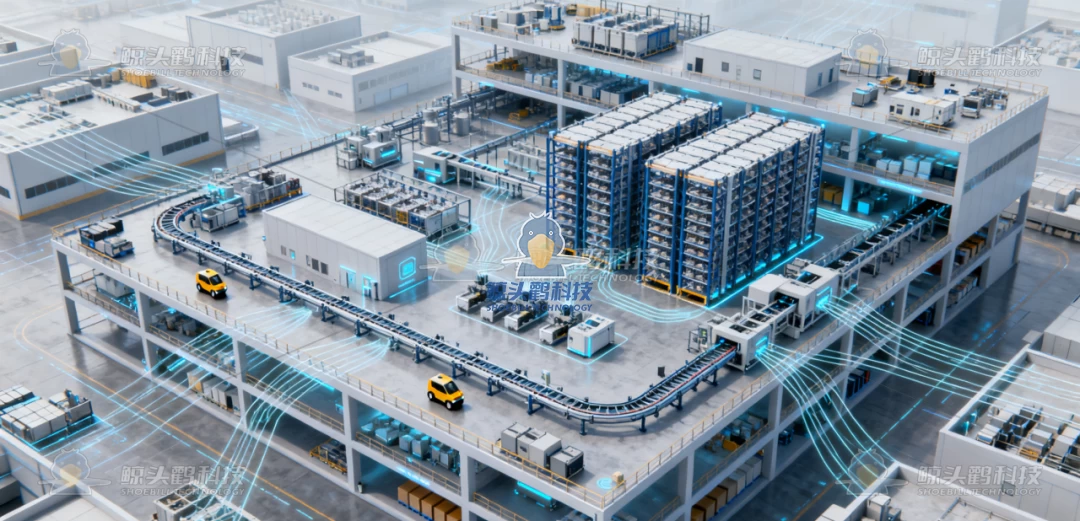

As the manufacturing industry accelerates toward intelligence and automation, multi-story factories are gaining popularity due to their high space utilization. However, the complex vertical and horizontal flow of materials often becomes a bottleneck for efficiency improvement. Traditional logistics systems that rely heavily on manual operations lead to high costs, low efficiency, frequent dispatch errors, and potential safety risks.

So, how can multi-story factories eliminate the need for logistics personnel and achieve a fully intelligent logistics loop?

This article breaks down a proven “zero logistics staff” smart logistics solution based on core principles of factory planning — helping enterprises unlock seamless and automated material flow.

Centralized Automated Warehouse Spanning All Floors: Solving Vertical Logistics Challenges

The greatest challenge in multi-story factory logistics lies in cross-floor material transfer. In conventional setups, workers transport materials between floors using elevators — a time-consuming and inefficient process that often results in inventory backlogs on different levels.

The key to solving this lies in a “centralized automated warehouse design”. By placing an automated storage and retrieval system (ASRS) in the central area of the factory, and integrating vertical lifts connecting all floors from the ground to the top, the ASRS becomes the core “vertical logistics hub.”

Serving as the “central dispatch center” of all factory materials — including raw materials, semi-finished products, and finished goods — the ASRS enables each production floor to operate without separate storage areas. Materials are stored or retrieved directly through designated in/out ports on each level.

For example, raw materials received and inspected on the first floor can be stored in the ASRS’s lower section. When the third-floor production line requires materials, the system automatically instructs the lift to deliver them precisely to the third-floor interface. Similarly, semi-finished products from the fifth floor can be returned to the ASRS for subsequent scheduling.

This design completely opens up the vertical logistics channel, enabling unmanned and uninterrupted material transfer across multiple floors.

AGVs Integrated with ASRS: Completing the “Last Mile” on Each Floor

After solving vertical logistics, the short-distance transfer of raw materials to production lines and finished goods back to storage on the same floor is handled by AGVs (Automated Guided Vehicles).

In this planning framework, AGVs are fully integrated with the central ASRS system. When the production system sends a material request, the ASRS automatically retrieves the required materials and places them at the AGV docking station. The AGV then follows a pre-mapped or laser-guided path to deliver materials precisely to the production line racks. Once production is complete, the AGV transfers finished goods back to the ASRS’s inbound port, forming a closed-loop flow of raw materials → production → finished goods on the same floor.

The entire process operates without manual driving or scheduling. The AGVs adjust their speed and routing dynamically according to production rhythms, minimizing labor intensity, material loss, and transfer errors.

Direct Conveyor Lines to Shipping Area: Eliminating Redundant Links

Traditionally, finished goods move from the ASRS to shipment through several intermediate steps — warehouse retrieval, temporary storage, and manual transfer to the shipping zone. This process is inefficient and prone to mix-ups caused by temporary stacking.

To overcome this, planners can install a fully automated conveyor line connecting the ASRS directly to the shipping area. The ASRS releases finished products automatically according to order requirements, and the conveyor delivers them straight to sorting stations or loading platforms — without any manual intervention.

For bulk truck orders, the conveyor can transport products directly to the corresponding loading bay. For small or multiple orders, the sorting system at the conveyor’s end automatically classifies goods by destination, ready for courier or logistics pickup.

This streamlined design eliminates redundant steps such as temporary storage and manual transfer, shortening the time from retrieval to shipment by over 50% while reducing order mix-up risks.

Centralized Material Feeding: Reducing Manual Involvement from the Source

Beyond main product logistics, the handling of auxiliary materials — such as screws, adhesives, or packaging — can also consume significant labor if each production line requests and moves them manually.

The solution: a centralized feeding system.

A dedicated auxiliary material warehouse is established within the factory. Based on production schedules, small AGVs or pipeline transport systems deliver auxiliary materials precisely to each line’s supply station at regular intervals. For instance, during assembly, mini-AGVs can deliver screws and nuts hourly; for packaging, a pipeline system can feed cartons and tapes directly to packaging stations.

This “proactive delivery” mode replaces the traditional “on-demand request” system, allowing each line to receive timely material replenishment without dedicated logistics staff — further advancing toward the “zero logistics personnel” goal.

Four Integrated Solutions: Building Complete Smart Logistics Ecosystem

From a central vertical warehouse spanning all floors, to AGVs managing intra-floor material flow, to conveyor lines directly reaching shipping ports and centralized material supply covering auxiliary material replenishment, these four core solutions do not exist independently. Instead, they form a comprehensive, seamless intelligent logistics system through interconnected systems.

This system, with its core goal of "reducing or even unmanning" operations, through the deep collaboration of equipment and systems, not only completely eliminates reliance on logistics personnel but also achieves efficient, precise, and cost-effective material flow. For multi-story factories, this represents not only an upgrade in logistics models but also a comprehensive improvement in production efficiency and management. When material flow no longer requires manual intervention, factories can focus more on optimizing production processes and improving product quality, truly entering a new era of intelligent manufacturing.

In the future, with the further penetration of technologies such as 5G, the Internet of Things, and AI, intelligent logistics in multi-story factories will achieve even more dynamic and intelligent upgrades, such as collaborative operation of AGVs and robots, and automatic inventory adjustments based on order forecasts in vertical warehouses. But no matter how the technology evolves, the planning logic of "based on space utilization and aiming at unmanned operation of the entire process" will always be the core competitiveness of intelligent logistics in multi-story factories.

[Shanghai Shoebill Technology]

Shoebill Technology will help you plan a user-friendly and affordable industry-leading factory!

Whether you're building a new plant or renovating an existing one, we offer comprehensive, one-stop services, including park planning, architectural design, layout planning, automation and logistics design, standardized industrial interior design, digital design, smart campuses, advanced visualization, and implementation support.

We prioritize implementation, ensuring your project becomes an industry benchmark upon implementation.

Clients include industry leaders such as Heli Forklift, Qianjiang Motorcycle, Giti Tire, Baoxiniao, and Yangquan Valve.

Mobile: 13262659820

Official Website: www.shoebilltech.com

Email: shoebill@balaena.cn